1 Introduction

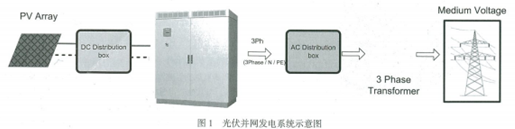

With the economic development, human’s demand for energy is growing and the sustainable development of energy is more and more important. The work theory of solar power is as follows: photovoltaic effect of solar cells converted the light energy into DC power, and converted DC power to AC power through the effect of inverter , then connected with the grid-generation.

Photovoltaic grid-connected inverter, as the interface device of solar battery and power grid, plays a vital role in the photovoltaic power generation system. At present, the inverter in photovoltaic power generation system mostly adopts a full-bridge inverter operating in the state of the SPWM. Inverters’ conversion efficiency and. MPPT’s precise tracking ability, have decisive influence on the whole solar power project investment returns. In this paper, from the angle of the performance index, the internal design of the inverter, introduces the performance of Powerstar’s high protection grade of central type photovoltaic grid-connected inverter.

2 Introduction of Powerstar inverter

2.1 High-quality outdoor case design

? Powerstar inverter regards providing high power generation efficiency of photovoltaic system as its design principle and meets Germany BDEW specifications. Its maximum conversion efficiency is more than 98.5%. IP54 protection grade design of chassis ensures the stable operation of internal device. IP54 rain-proof/sand prevention design of the inverter makes inverters suitable for indoor or outdoor environment, without buiding power distribution room, so it can reduce the additional construction cost besides system. Outdoor cabinet shape is shown in figure

2.2 Superior heat dissipation design

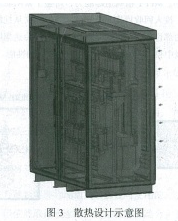

Powerstar central inverter adopts natural air circulation to reduce machine temperature, which not only reduces the energy loss caused by the cooling system, but also enhances the stability of the whole machine. The natural cooling cycle squeezes the hot air out from the upper air outlet and makes the equipment work within the temperature range as required.

The inside of the case is divided into two completely separate space with all the electronic components installed in the front space and the back used to radiating hot air, see figure 3. The two space is separated by the IP54 protection to avoid convection of hot air and the impact of dust, so as to ensure the efficiency of the system work . The IP54 protection level greatly improved

the durability of the internal electronic devices and ensured the stable operation of equipment.

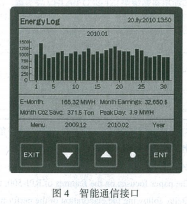

2.3 Intelligent communication interface

5 inch LCD display interface is easy to inquery and set daily operation, see figure 4. The data recorder in inverter will automatically store power data produced in different periods of the solar system and important information can be stored for up to 10 years.

Each 5 min record of generating data will be storaged for one day. Each 15 min record of generating data will be storaged for a month.

The daily generation data by solar system will be storaged for a month. The monthly generation data by solar system will be storaged for 10 years.

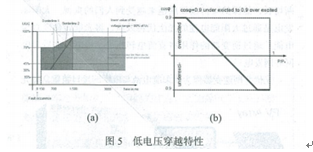

2.4 Low Voltage Ride Through and reactive compensation

Powerstar’s central inverter has passed the Certification of the German BDEW regulations, and it is in line with China's CGC-SOLAR and LVRT. LVRT (Low Voltage Ride Through) ensure that the solar system can provide reactive power when power grid is instable, so as to maintain consistency of power system and grid consistent, which can not only avoid the system’s repeated start caused by electric network instability, but also helps to improve power generation efficiency of solar system.

When the inverter is connected to the distribution network, LVRT will automatically start and work at preset mode . The related parameters of LVRT can be set based on local grid code requirements.

2.5 Unique design

Powerstar’s inverter is 1600 x 1950 x 800mm large and weighs 1250 kg. Compared with other 500kW inverter, its volume, weight were reduced by more than 1/3, which makes it convenient to be transported and installed. The inverter is more elastic for space. Fault protection design: driven by two sets of 250kW design. When any of a group of components occurs failure or damage, it can still maintain the working efficiency of 250kW so as to reduce the loss of shutdown.

3 Conclusion

In summary, Powerstar 500kW inverter adopts no isolation transformer design and its peak conversion efficiency is as high as 98.5%. Unique cooling air duct design prolongs the service life of the internal electronic components, fault protection design minimizes the system’s power generation loss when faults occur to a group of components and reduces the risk of appliation. IP54 high protection ensure the good environment adaptability and stability of equipment. Powerstar inverter will bring mor eexpectations and surprise for customers in PV system solutions.

Copyright © 2003 - 2023 . All Rights Reserved

Copyright © 2003 - 2023 . All Rights Reserved